Recently, in the defense review of the key 2020 annual declaration project of "Green biological manufacturing" organized by the Biological Center of the Ministry of Science and Technology, one of the six tasks of "industrial enzyme creation and application" has attracted widespread attention in the industry. Industrial enzyme preparations are biological products with catalytic function after enzyme processing and compounding, which is a relatively mature and potential core industry in industrial biotechnology, with tens or even hundreds of times the downstream market amplification effect, so it is known as the "chip" of the biological manufacturing industry.

At present, more than 3,000 kinds of enzymes have been reported to have been discovered in the world, and more than 60 kinds of enzyme preparations have been achieved large-scale production. It is widely used in washing, textile, feed, food, juice processing, dairy products, leather, paper, medicine, chemical and other industries, and the application technology level is constantly improving. Industrial organisms use living cells or their enzymes as tools to synthesize chemicals, with clean, renewable and other characteristics, and have the potential to change the world's industrial structure in the fields of energy, chemicals and medicine, creating a new era of wealth growth. According to Novozymes data, as a green catalyst, compared with the petrochemical route, the current energy saving and drainage of bio-manufacturing products can reach 30%-50%, and the future potential will reach 50%-70%.

Sichuan Bohaoda Biotechnology Co., LTD

Large-scale production of inositol using global multi-enzyme molecular machines, in October 2019, the world's first 10,000 tons of green and environmentally friendly process enzyme catalyzed intelligent inositol production base - a high-tech park (built in accordance with pharmaceutical GMP standards), the park has created the world's first use of microbial green ecological technology to achieve the industrialization of inositol and its derivatives. The traditional production method of inositol hydrolyzed by phytic acid with high pollution and high energy consumption is replaced by a green production method with no pollution and low energy consumption, so as to achieve a leapfrog change of high quality of inositol products, energy saving and production cost saving (about a quarter of the traditional process).

The production base adopts the most advanced international construction method, adopts the global enterprise intelligent equipment and hardware, realizes the automatic intelligent system from the feeding to the production cost, eliminates the employee's misoperation or affects the product quality, and uses the food-grade raw materials to produce high-quality inosiol throughout the process.

At present, the company has built an intellectual property protection system, around the inositol products and its application, has applied for a total of 32 invention patents in China, the United States, the Netherlands, Italy, Belgium, Japan, South Korea, Thailand, Vietnam 10 countries, has been authorized by China, the Netherlands, the United States, Italy, Belgium, South Korea, Japan, Thailand, Vietnam 28 invention patents.

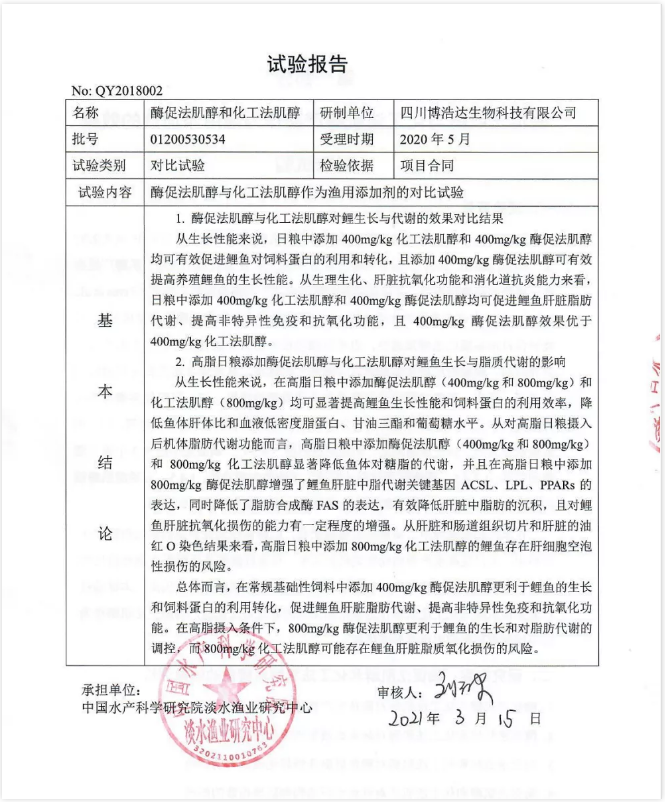

The Chinese Academy of Fisheries Research concluded that enzymatic inositol was more beneficial to the growth of animals and the utilization and transformation of feed protein, promoted the liver fat metabolism of animals, and provided non-specific immune and antioxidant functions. Chemical inositol can cause oxidative damage of animal liver lipids.

With unique technical advantages, Bohaoda Biological has successfully established sales partnerships with feed, food and pharmaceutical enterprises in the United States, Germany, France, Britain, Japan, Italy, the Netherlands, Thailand, India, Vietnam, Brazil, South Korea and other countries, and its products are exported to the world. Through the expansion and extension of the industrial chain, Bohaoda is expanding the market value and promoting the formation and development of green biological industry clusters.